Drive

Pulley

Efficiently transfer power from the driving source to the driven component in a belt drive system

Drive Pulley

What a drive pulley is?

A drive pulley is a pulley that is attached to a power source, that when in use puts force on a belt (or cable or chain). The belt is connected to the object being driven, which will then spin. This is a type of power transmission.

In some applications, drive pulleys are used in conjunction with timing belts or chains to achieve precise synchronization and timing. This is critical in systems that require precise positioning, coordination or component sequencing, such as engines, conveyor systems and robotics. By using the timing Belt pulley, the drive pulley can be used in conjunction with timing belts or chains to ensure the accuracy and reliability of the transmission system, thereby achieving precise position control and coordinated movement.

Applications

Conveyor Systems

Drive pulleys are extensively used in conveyor systems found in industries like mining, manufacturing, logistics, and agriculture.

Industrial Machinery

Drive pulleys are employed in a wide range of industrial machinery, including pumps, compressors, generators, and packaging equipment.

HVAC Systems

Drive pulleys are used in heating, ventilation, and air conditioning (HVAC) systems to power fans, blowers, and pumps.

Automotive Industry

Drive pulleys play a crucial role in automotive applications, such as in the engine’s accessory drive system. They power components like the alternator, water pump, power steering pump, and air conditioning compressor.

Agricultural Equipment

Drive pulleys are utilized in agricultural machinery like combine harvesters, tractors, and irrigation systems. They help drive components such as grain augers, belts, and pumps, enabling efficient farming operations.

Printing Presses

Drive pulleys are an essential part of printing presses, facilitating the movement of paper or other printing substrates through the press. They ensure accurate and synchronized paper feeding and delivery during the printing process.

Key Features

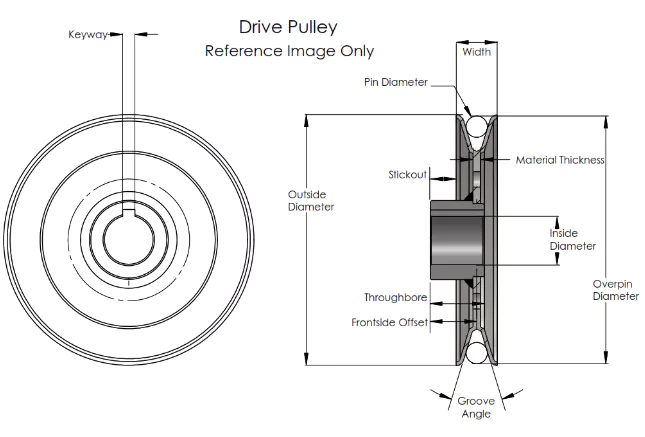

- Size and Configuration: Drive pulleys come in various sizes and configurations to accommodate different power transmission requirements.

- durable materials: such as steel, aluminum, or cast iron to withstand the forces and stresses involved in power transmission.

- Surface Design: The surface of drive pulleys is designed to provide frictional contact with the belt, ensuring reliable power transfer.

- Belt Compatibility: Drive pulleys are designed to match the specifications of the belt used in the drive system, ensuring proper alignment and engagement for efficient power transmission.

- Hub and Shaft Connection: Drive pulleys have a hub that connects to the shaft of the driving source, ensuring a secure and reliable connection to transmit rotational force.

- Load Capacity: Drive pulleys are engineered to handle specific loads and torque requirements

- Designed for ease of maintenance

How To Choose a drive pulley

- Ensure Power Requirements: Evaluate the power transmission needed to meet the torque and speed requirements of your equipment, and select a drive pulley accordingly.

- Consider Load Requirements: Choose an appropriate drive pulley based on the characteristics of your equipment’s load. Consider the size, nature, and variability of the load to select a suitable size and material that can effectively transmit and bear the load.

- Match with Belt Drive Systems: Ensure the selected drive pulley matches the specifications, size, and characteristics of the belt or chain drive system being used. This ensures efficient power transmission and accurate synchronization.

- Account for Environmental Factors: Select a durable drive pulley that can withstand the demands of your working environment. Consider factors such as temperature, humidity, and chemical exposure, and choose a drive pulley that can adapt to the environmental conditions while meeting material and lubrication requirements.

If you have any questions or are confused about choosing a product, please feel free to contact us.

How To Maintain

- Regular Inspection: Regularly inspect the appearance and operational condition of the drive pulley. Look for any signs of damage, wear, or loose components, and take prompt repair measures.

- Cleaning and Maintenance: Keep the drive pulley clean and promptly remove accumulated dust, grease, or other debris. Use appropriate cleaning agents and tools, avoiding corrosive substances.

- Adjustment and Alignment: Ensure proper alignment between the drive pulley and the transmission system. Adjust tension and belt tightness as necessary to ensure smooth power transmission and prolong the lifespan of the pulley.

- Lubrication: Regularly lubricate the drive pulley according to the manufacturer’s recommendations. Use suitable lubricants and pay attention to the appropriate quantity and frequency of lubrication.

Why Choose Us

Vivamus magna justo, lacinia eget consectetur sed, convallis at tellus. Proin eget tortor risus. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Vestibulum ac diam sit amet quam vehicula elem

Get Free Quote!